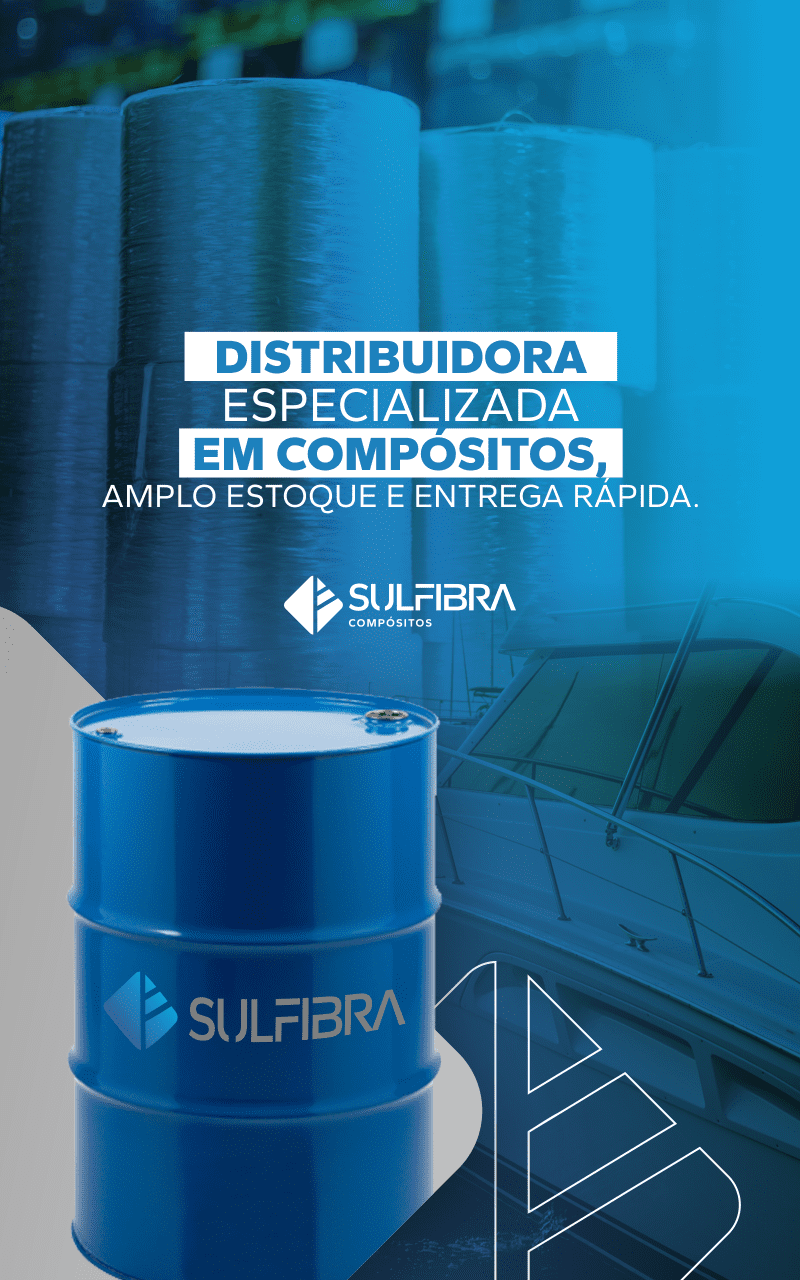

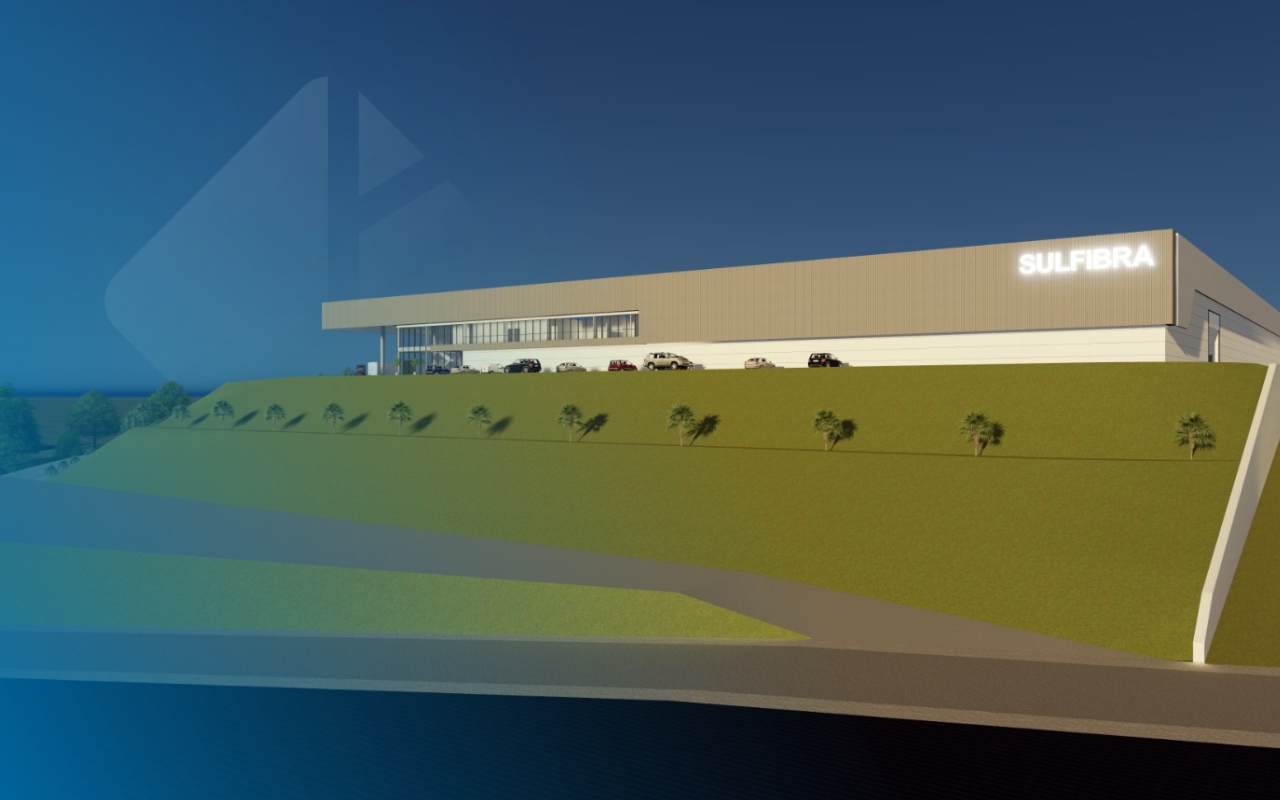

Sulfibra anuncia Projeto e Início das Obras para Nova Planta Fabril em Videira, Santa Catarina: Um Novo Horizonte de Oportunidades

É com grande entusiasmo que a Sulfibra, empresa de renome na região, orgulhosamente anuncia seus planos para estabelecer uma nova planta fabril em Videira, Santa Catarina…